Technical capabilities of laser metal cutting (Fiber):

- Laser power: 1.5 kW

- Working area: 1500mm x 3000mm

Materials to be cut:

- Aluminium up to 5 mm thick

- Carbon steel up to 15 mm thick

- Stainless steel up to 6 mm thick

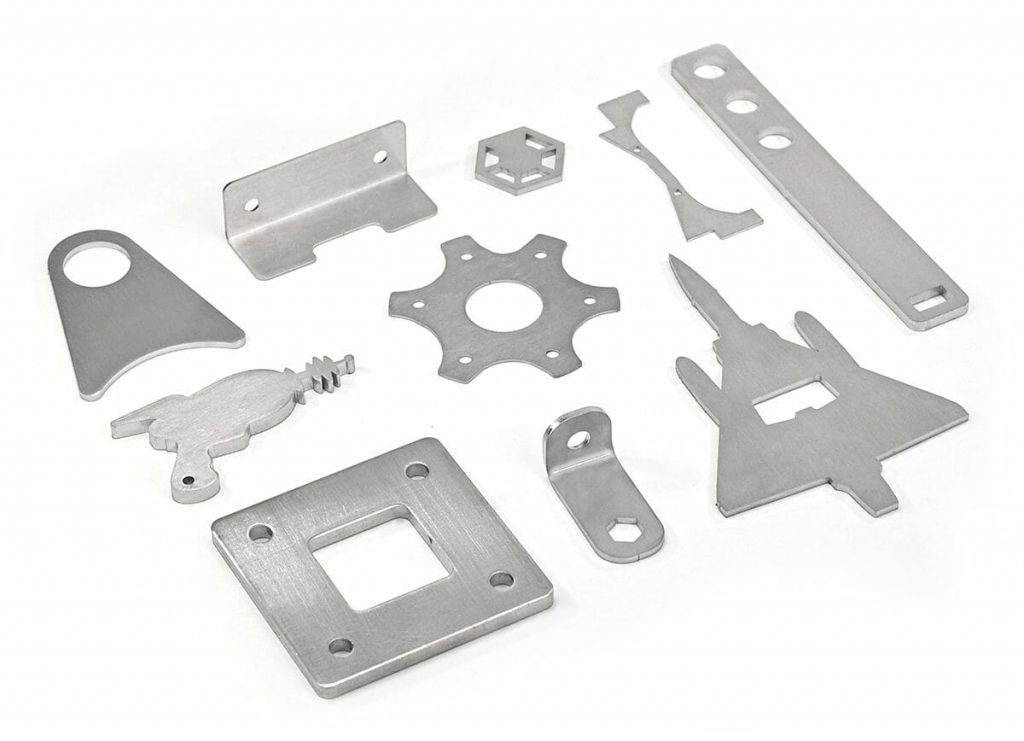

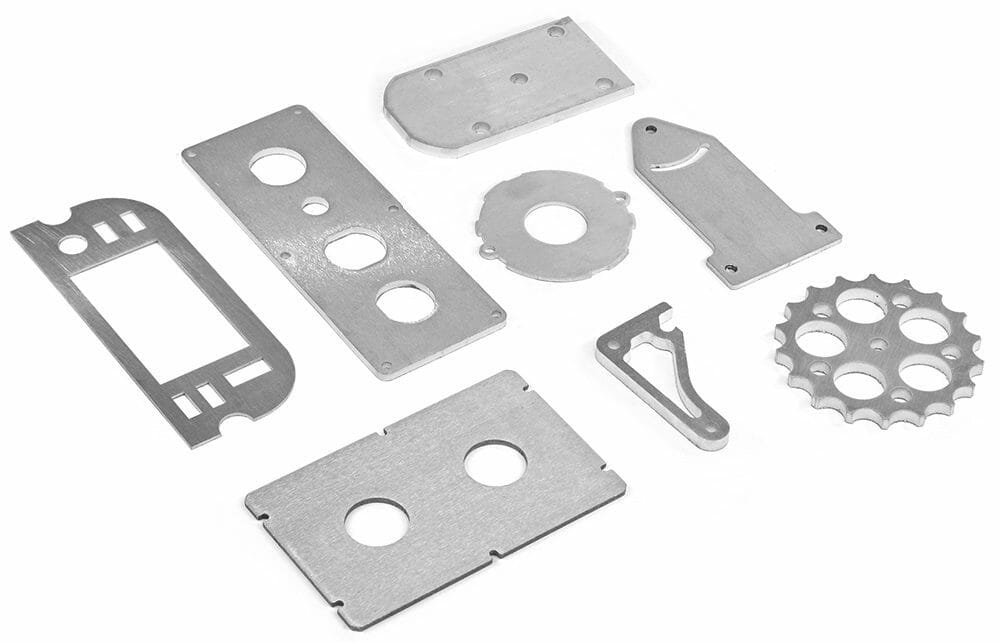

Metal laser cutting is a complex but versatile and efficient manufacturing process that uses a high-powered laser beam to cut sheet materials. The process involves directing a laser beam at the material using a computer-controlled system, which allows precise cuts and shapes to be made.

One of the main advantages of laser cutting is the ability to cut materials with great precision and accuracy. The laser beam is so precise that it can cut materials to within 0.1 mm of the desired shape. This precision makes laser cutting the ideal choice for applications requiring small tolerances, such as the manufacture of automotive parts and electronic components.

Another advantage of laser cutting is its speed. Laser cutting machines can make cuts much faster than other methods such as hand cutting or machining. This makes it a cost-effective choice for mass production, as well as for one-off prototypes and small series.

After laser metalworking, we can also offer a plating service for stainless steel and aluminium parts.